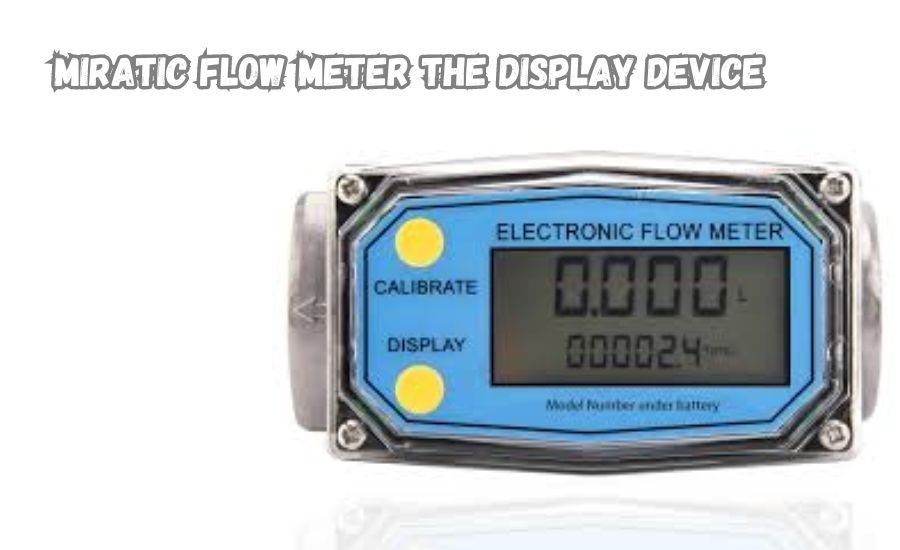

Miratic Flow Meter the Display Device is transforming the way industries measure fluid flow with unmatched precision. This advanced tool combines cutting-edge technology with an intuitive display, making it essential for applications ranging from chemical processing to water treatment. By providing real-time data, the Miratic Flow Meter ensures that every measurement is accurate and reliable, leading to smoother operations and improved efficiency.

Miratic Flow Meter the Display Device offers a range of features that cater to various industrial needs. Its user-friendly interface allows operators to monitor and adjust flow rates easily, while its robust construction ensures durability even in challenging environments. Whether you’re managing a manufacturing line or overseeing water treatment facilities, understanding the benefits of this sophisticated device can lead to significant enhancements in your workflow.

Understanding the Miratic Flow Meter the Display Device: A Comprehensive Overview

The Miratic Flow Meter the Display Device is an advanced tool used to measure the flow of liquids or gases through a system. This device is crucial for various industries because it provides precise, real-time measurements, ensuring smooth operations and accurate monitoring. Whether you’re working in manufacturing, water treatment, or any sector requiring precise flow measurements, this device is designed to deliver reliable data.

In simpler terms, imagine the Miratic Flow Meter as a high-tech speedometer for fluids. Just as a car’s speedometer tells you how fast you’re going, this device shows how fast a liquid or gas is moving through a pipe or system. By providing immediate feedback on flow rates, it allows for better control and management of the processes where it’s used.

The Miratic Flow Meter features a display that provides real-time information about the flow rate. This immediate access to data means you don’t have to wait for periodic reports or manual checks. It helps in making timely decisions and adjustments to keep processes running smoothly. The accuracy and reliability of this device make it a valuable tool for maintaining operational efficiency and quality control.

In various applications, from industrial plants to municipal water systems, the Miratic Flow Meter ensures that everything operates within the desired parameters. Its ability to deliver precise measurements in real-time makes it indispensable for managing flow rates effectively, thereby preventing potential issues and optimizing performance.

How the Miratic Flow Meter the Display Device Enhances Precision in Fluid Measurement

The Miratic Flow Meter the Display Device is known for its exceptional precision in measuring flow rates. Precision is crucial in many industries because even minor inaccuracies can lead to significant problems. This device uses advanced technology to ensure that every measurement is accurate and reliable, providing peace of mind and operational efficiency.

Importance of Accurate Measurements

Accurate measurements are essential for maintaining product quality and process stability. For example, in chemical processing, the exact flow rate of chemicals is critical for creating the right mixture. If the flow rate is off, it can affect the product’s quality and potentially lead to hazardous situations. The Miratic Flow Meter ensures that measurements are spot-on, helping prevent such issues and ensuring that processes remain safe and effective.

Real-Time Display and Adjustments

The device’s real-time display feature allows operators to see flow rates as they happen. This immediate feedback is vital for making quick adjustments and addressing any anomalies right away. For instance, if there’s a sudden change in flow rate, operators can make adjustments promptly to keep the process stable. This capability is especially valuable in high-speed or sensitive operations where timing and accuracy are critical.

Versatility in Measurement

The Miratic Flow Meter is designed to handle a variety of fluids and gases, making it a versatile tool across different industries. Its ability to provide accurate measurements for various substances ensures that it can be used in diverse applications, from water treatment to chemical manufacturing. This versatility adds to its value, making it a reliable choice for many different settings.

Key Benefits of Using the Miratic Flow Meter the Display Device in Various Industries

The Miratic Flow Meter the Display Device offers numerous benefits across different sectors, enhancing both efficiency and safety. Here are some of the key advantages:

- Real-Time Data and Immediate Decision-Making: The device provides up-to-date flow rate information, allowing operators to make informed decisions quickly. Immediate data helps in maintaining smooth operations and addressing any issues as they arise.

- Cost Savings through Efficiency: Accurate flow measurements help in reducing waste and optimizing resource use. This efficiency translates into cost savings and improved profitability by preventing unnecessary expenses and resource wastage.

- Enhanced Safety Measures: Precise flow measurement is crucial for maintaining safety in industrial processes. The Miratic Flow Meter ensures that operations stay within safe parameters, helping prevent accidents and ensuring compliance with safety standards.

Real-Time Data with the Miratic Flow Meter the Display Device: Why It Matters

One of the standout features of the Miratic Flow Meter the Display Device is its capability to provide real-time data. This feature is critical because it allows for continuous monitoring and immediate response to changes in flow rates. Real-time data ensures that operators can manage processes effectively and make adjustments on the fly.

Immediate Feedback for Quick Adjustments

Real-time data means that any fluctuations or issues in flow rates are detected instantly. This allows operators to make quick adjustments, preventing potential problems from escalating. For instance, if a sudden change in flow rate is detected, adjustments can be made immediately to stabilize the process. This immediate feedback helps in maintaining smooth and efficient operations.

Improved Process Management

Having access to real-time data enhances overall process management. Operators can track flow rates continuously and ensure that processes are running as expected. This constant monitoring helps in identifying trends and making proactive adjustments. For example, in a manufacturing plant, real-time data helps in optimizing production processes and ensuring that everything operates within desired parameters.

Troubleshooting and Issue Resolution

Real-time data also aids in troubleshooting issues. If there is an unexpected change in flow rate, it can be quickly identified and addressed. This reduces the likelihood of prolonged downtime and helps in maintaining operational efficiency. The ability to detect and resolve issues promptly ensures that processes remain stable and productive.

Choosing the Right Miratic Flow Meter the Display Device for Your Needs

When selecting a Miratic Flow Meter the Display Device, it’s important to choose one that fits your specific needs. Consider the flow measurement range required for your application. Different models offer various ranges, so pick one that matches your requirements.

Accuracy is another key factor. Make sure the flow meter you choose provides the precision needed for your processes. The Miratic Flow Meter is known for its high accuracy, but ensure that it meets the specific needs of your operation.

Compatibility with the fluids or gases being measured is also crucial. Ensure that the device can handle the type of substance you’re working with. This ensures that you get reliable measurements without any issues.

Ease of installation is another aspect to consider. A flow meter that is easy to set up will save you time and reduce the risk of errors during installation. Choose a model that fits well with your existing system and is straightforward to integrate.

The Role of User-Friendly Interfaces in the Miratic Flow Meter the Display Device

The Miratic Flow Meter Display Device features a user-friendly interface that plays a significant role in making the device easy to operate. A well-designed interface is crucial for ensuring that users can quickly and effectively manage flow measurements.

Simple and Intuitive Navigation

- Easy to Understand Layout: The interface is designed with a straightforward layout that helps users navigate through the various functions effortlessly. This simplicity reduces the learning curve and makes it accessible for both new and experienced users.

- Clear Instructions: On-screen instructions guide users through setup and operation, minimizing the chances of errors. This ensures that users can quickly understand how to use the device without extensive training.

Clear and Readable Display

- High Contrast Screen: The display features high contrast and clear text, making it easy to read data even in different lighting conditions. This clarity helps users quickly grasp the information presented.

- Large Display Fonts: Fonts are large and legible, allowing users to view data without straining their eyes. This feature is especially useful for operators who need to monitor measurements from a distance.

Reduced Error Risk

- Error Alerts and Notifications: The device includes alerts and notifications for common issues, helping users identify and correct problems promptly. This feature reduces the risk of operational errors and ensures accurate measurements.

- Guided Troubleshooting: Built-in troubleshooting guides assist users in resolving issues without needing technical support. This feature enhances user confidence and helps maintain the device’s performance.

The user-friendly interface of the Miratic Flow Meter ensures that operators can efficiently manage flow measurements, reducing the risk of errors and improving overall operational efficiency.

The versatility of the Miratic Flow Meter the Display Device: Applications Across Industries

The Miratic Flow Meter the Display Device is known for its versatility, making it suitable for a wide range of applications across different industries. Its ability to handle various fluids and gases adds to its value in diverse settings.

Applications in Chemical Processing

In chemical processing, precise flow measurement is essential for maintaining product quality and safety. The Miratic Flow Meter provides accurate data for controlling the flow of chemicals, ensuring that the right amounts are used. This helps in preventing errors and maintaining the integrity of the production process.

Use in Water Treatment Facilities

Water treatment facilities benefit greatly from the Miratic Flow Meter’s capabilities. It monitors the flow of water through different stages of treatment, ensuring that processes are running efficiently. Accurate flow measurement helps in maintaining water quality and meeting regulatory standards.

Utility in Oil and Gas Industry

The oil and gas industry relies on precise flow measurement for exploration and production. The Miratic Flow Meter provides the accuracy needed for monitoring and controlling flow rates in these critical applications. Its reliability and versatility make it a valuable tool in managing complex processes in the industry.

Benefits in Food and Beverage Sector

In the food and beverage sector, consistent flow rates are crucial for product quality. The Miratic Flow Meter helps in maintaining accurate measurements, ensuring that production processes are efficient and products meet quality standards. Its adaptability makes it a useful tool in various food and beverage applications.

Maintaining Your Miratic Flow Meter the Display Device for Optimal Performance

Regular maintenance is key to keeping the Miratic Flow Meter the Display Device working well. One important aspect of maintenance is calibration. Calibration ensures that the device remains accurate and provides reliable measurements over time.

Cleaning the flow meter is also crucial. Dirt or build-up can affect its performance. Follow the manufacturer’s guidelines for cleaning to prevent any issues that might arise from a dirty device.

Regular inspections help in identifying any signs of wear or damage. By addressing issues early, you can avoid more significant problems and ensure that the device continues to function properly.

If your Miratic Flow Meter includes software, keep it updated. Software updates can provide new features and improvements, ensuring that your device stays current with the latest technology.

Hope You Interesting:

Troubleshooting Common Issues with the Miratic Flow Meter the Display Device

Knowing how to troubleshoot issues with the Miratic Flow Meter the Display Device can help in keeping the device running smoothly. Here are some common problems and solutions:

- Inaccurate Readings: If the device is showing inaccurate readings, it could be due to calibration errors. Check the calibration settings and make adjustments as needed to ensure accuracy. Inaccurate measurements can lead to operational issues, so it’s important to address this promptly.

- Malfunctioning Display: If the display is not functioning correctly, ensure that all connections are secure and that the device is clean. Sometimes, a simple reset can resolve display issues. If the problem persists, consult the user manual or contact customer support for further assistance.

- Persistent Problems: For persistent issues that cannot be resolved through basic troubleshooting, consult the user manual for additional tips or seek help from customer support. Professional assistance may be necessary for complex problems that require specialized knowledge or repairs.

The Future of Fluid Measurement: Innovations in the Miratic Flow Meter the Display Device

The Miratic Flow Meter the Display Device is continuously evolving with technological advancements. The future of fluid measurement includes innovations that enhance accuracy, ease of use, and integration with other systems.

Improved Sensors and Software

Future models of the Miratic Flow Meter may feature advanced sensors and software for even greater precision. These improvements will help in providing more detailed and accurate measurements, making the device even more effective in various applications.

Integration with Smart Technologies

Upcoming flow meters might connect with other smart technologies for enhanced data analysis and process optimization. Integration with centralized systems will make it easier to manage and monitor flow rates, improving overall efficiency and performance.

Enhanced Performance Capabilities

As technology advances, the performance capabilities of the Miratic Flow Meter are expected to expand. These developments will continue to improve the device’s functionality and versatility, ensuring that it remains a valuable tool for fluid measurement in the future.

Overall, the future of the Miratic Flow Meter looks promising with ongoing innovations that will enhance its performance and capabilities, making it even more useful for a wide range of applications.

Conclusion

In summary, the Miratic Flow Meter the Display Device is a game-changer for anyone needing accurate flow measurements. Its easy-to-use interface makes it simple for anyone to operate, whether you’re new to the device or have used similar tools before. With clear displays and helpful alerts, it helps you get the right data without hassle.

Overall, using this device can make your work smoother and more efficient. By providing precise measurements and making it easy to read and manage data, the Miratic Flow Meter helps you keep everything running smoothly. It’s a smart choice for any industry that relies on accurate fluid measurements.

FAQs

Q: What is the Miratic Flow Meter the Display Device used for?

A: The Miratic Flow Meter the Display Device measures the flow rate of liquids and gases. It provides real-time data to ensure accurate monitoring and control in various industrial processes.

Q: How accurate is the Miratic Flow Meter the Display Device?

A: The Miratic Flow Meter the Display Device is highly accurate, providing precise measurements essential for maintaining optimal operational conditions and preventing errors.

Q: Can the Miratic Flow Meter handle different types of fluids?

A: Yes, the Miratic Flow Meter the Display Device can measure a wide range of fluids, including water, chemicals, and gases, making it versatile for various applications.

Q: How does the Miratic Flow Meter the Display Device improve safety?

A: It enhances safety by providing accurate flow measurements, which helps prevent issues like leaks and overflows, reducing the risk of accidents and ensuring safe operations.

Q: How often should the Miratic Flow Meter be calibrated?

A: Calibration should be performed regularly according to the manufacturer’s guidelines to maintain the accuracy and reliability of the Miratic Flow Meter the Display Device.

Q: What maintenance is required for the Miratic Flow Meter?

A: Regular maintenance includes cleaning, inspecting for wear, and checking calibration. Keeping the device in good condition ensures accurate performance and longevity.

Q: Where can the Miratic Flow Meter the Display Device be used?

A: It can be used in various industries, including chemical processing, water treatment, oil and gas, food and beverage, and pharmaceuticals, wherever precise flow measurement is needed.

Stay in touch to get more updates on TECH DENSER